- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

BAOFENG BF-870E Linear Machining Center

X/Y/Z Axis are linear guide way, 3 axis standard rapid feed 12 m/min.High rigidity machine body ensures cutting requirements can be met. High precision, high rigidity machine body maintains the processing stability during high rotation speed. Special reinforced spindle case design, the cutting strength increased 20% in comparison with similar models .

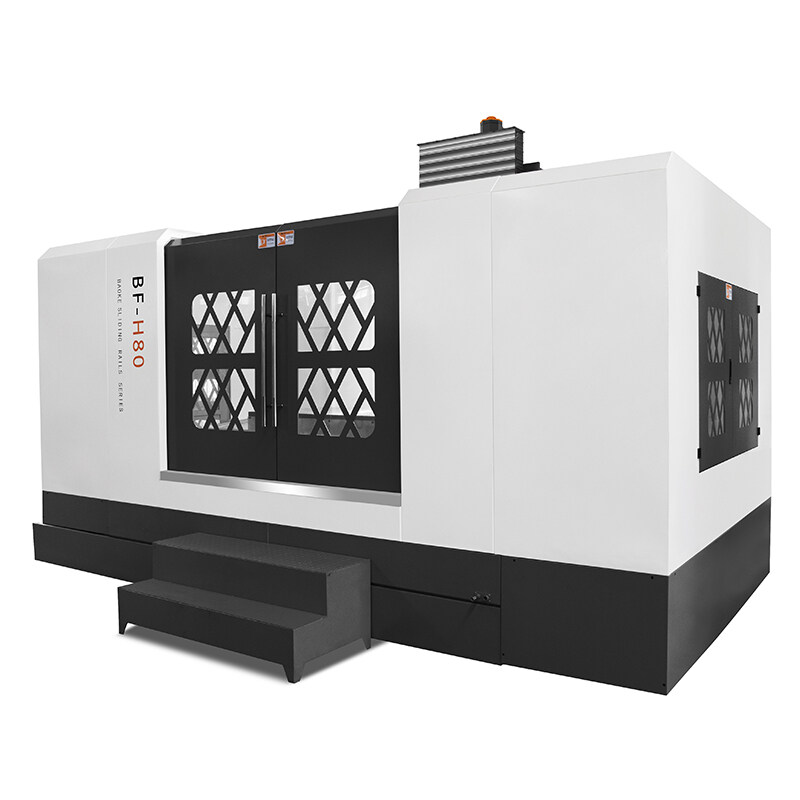

Horizontal Machine Center BF-H80

The HF-H80 Horizontal Machining Center is a high speed, high precision and complete integrated machine tool for processing box, shell and special-shaped parts in automobile, motorcycle, especially auto engine shells and reducer shells. The machine is used in many molding industries to process products with gears such as agricultural machinery and mining machinery etc.

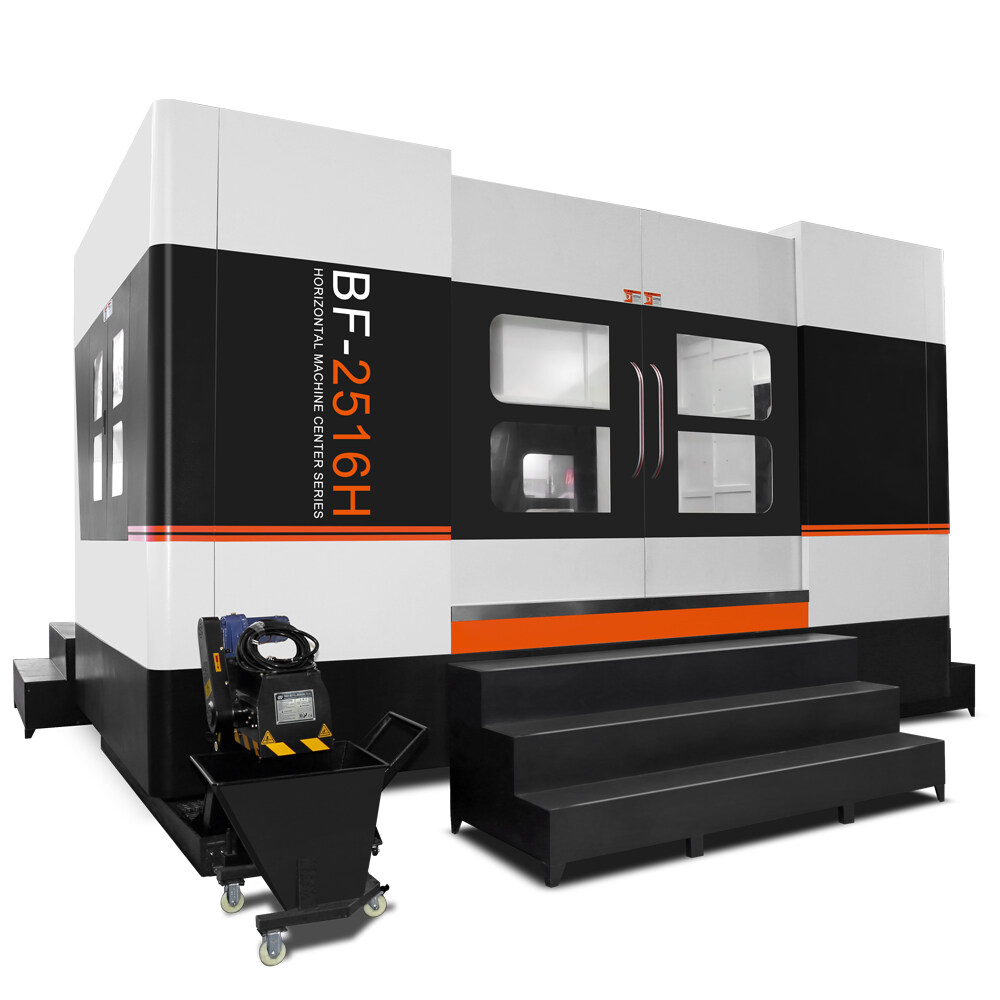

Horizontal Machine Center BK-2516H

With the use of advanced technology, our basic large parts adopt first-class research and development methods such as brand-new mineral materials, three-dimensional synchronous design, FEM finite element analysis, etc. We carry out a reasonable layout to ensure good anti-distortion and anti-bending ability of basic large parts

Horizontal Machine Center BK-1814L

The T-type base, full support structure for each axis, makes the machining accuracy more stable; Large capacity tool magazine and strong processing adaptability. Single and double exchange pallets are optional. Automatic chip removal reduces cleaning downtime. Wide processing range suitable for processing all kinds of mechanical parts

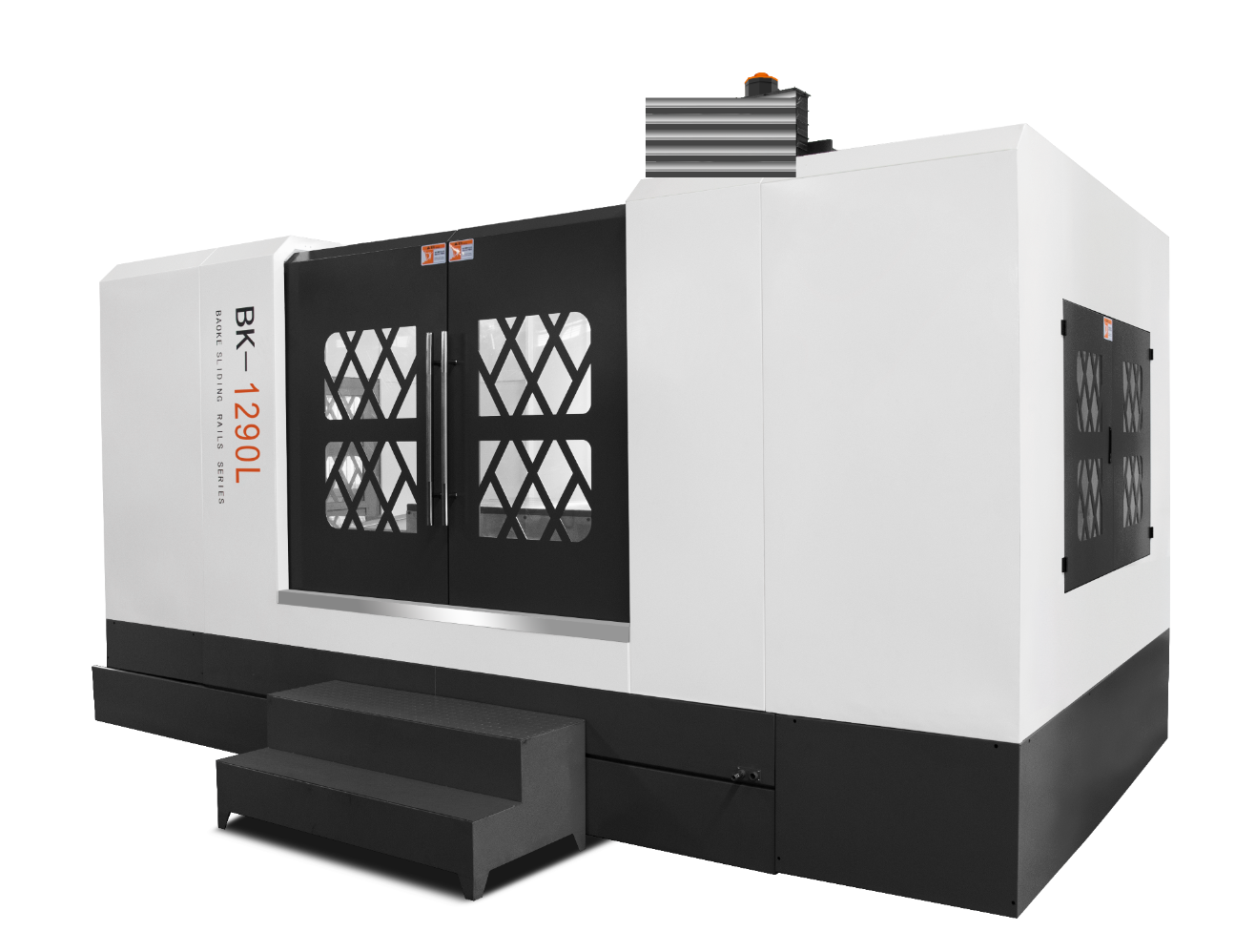

Horizontal Machine Center BK-1290L

The casting material of HT300 is mostly in the form of strips, flakes, low dust ratio and processing surface color close to steel. Our guide rails are more precise than those on the market ground by a milling machine and not scraped by hand. The construction process of every step is standardized, even for each screw. And we have strict inspection standards to inspect the static and dynamic precision of the machine body and whole machines

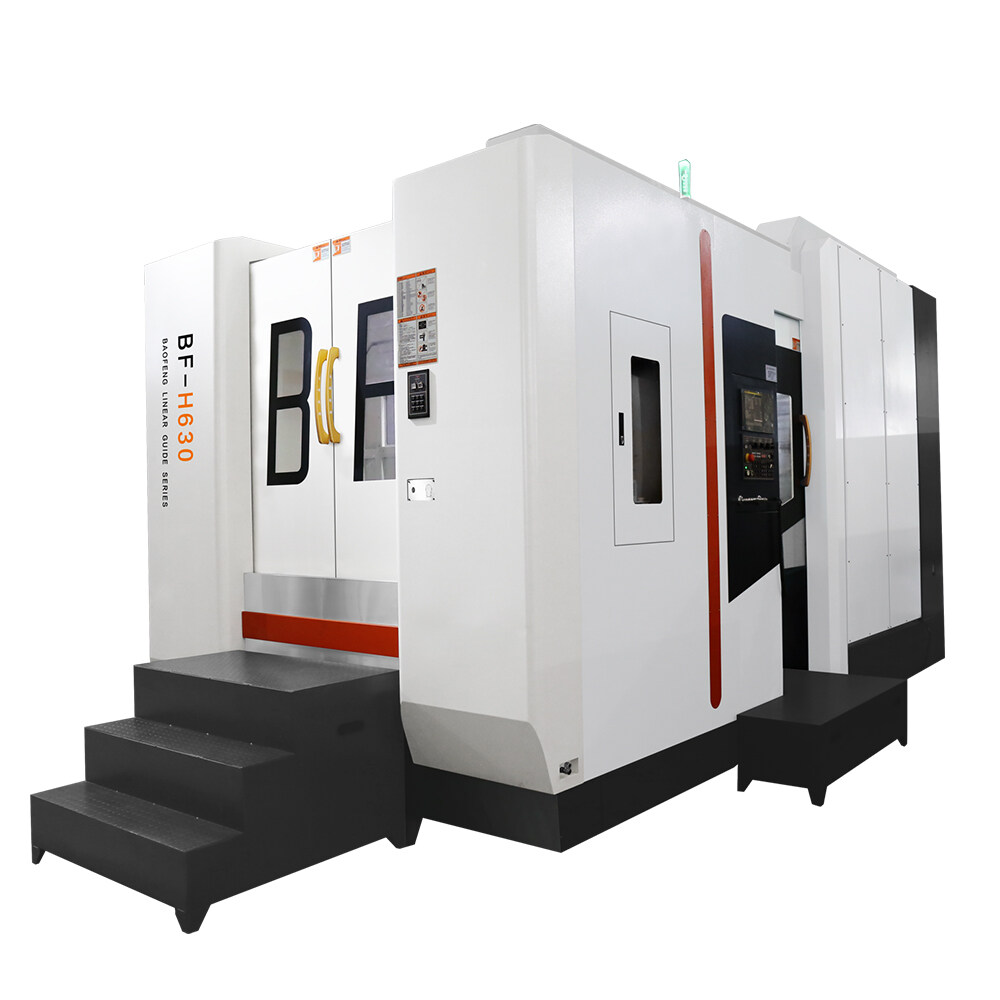

Horizontal Machine Center BF-630H

The X-axis parallel rail adopts a stepped distribution to enhance the rigidity of the column when cutting in the Z-axis direction. The base is supported by a large span to ensure the stability of the whole machine. The key components have passed finite element analysis to ensure the stability and rigidity of the machine.

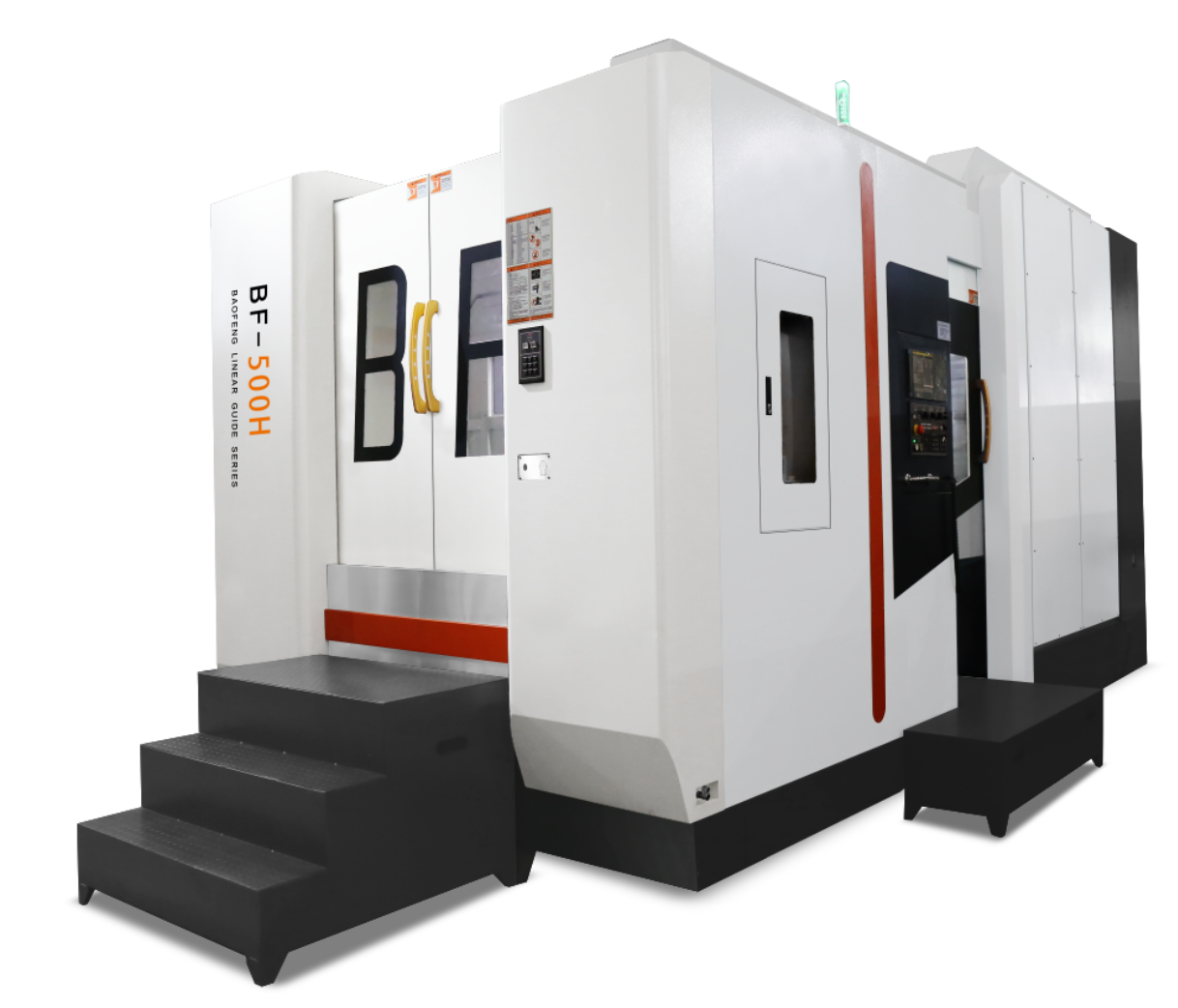

Horizontal Machine Center BF-500H

Our horizontal milling machine allows for low-angle cutting, especially on the side of the workpiece. It is suitable for machining very large parts and complex geometries. This configuration facilitates chip evacuation and tool change time is fast. It offers a pallet change function and it is more suitable for heavy parts requiring machining on several sides!

BAOFENG BF-650E Graphite Engraving Machining Center

X/Y/Z axis are linear guide way, 3 axis standard rapid feed 12 m/min. High precision, high rigidity machine body maintains the processing stability during high rotation speed. Special reinforced spindle case design, the cutting strength increased 20% in comparison with similar models . Coupling, spindle bearing, spindle, ball screw, and other key parts are imported from Germany, Japan and Taiwan top brands to ensure high quality and stability.