- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

BAOFENG V10 Linear way machining center

The machine tool is of C-type structure, mainly composed of table, column, saddle, base, spindle box, hydraulic system, lubrication system, cooling, and filtering system, electric control system. Adopt large span support for the main structure to make sure that the casting has the best deformation resistance structure. The body is designed by Finite Element Analysis (FEA) to ensure the stability and rigidity of the mechanism. Meanwhile, it enhances both torsional and bending resistance by adopting M-type support design. Large span herringbone column design increases rigidity with larger contact surface between column and base.

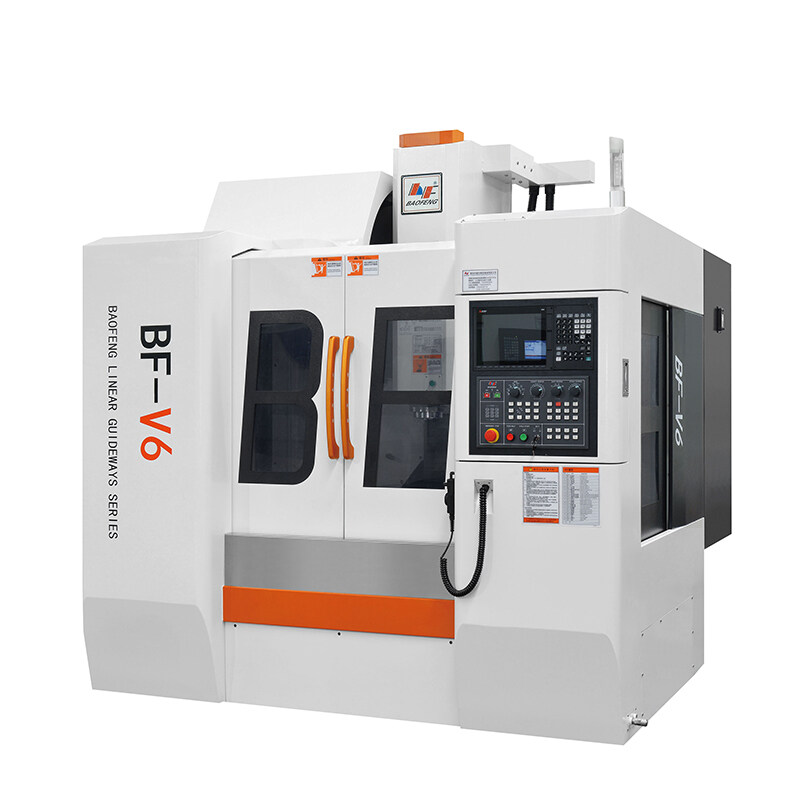

BAOFENG V6 Linear way machining center

With the rigidity, stability, high speed and high precision moving parts, it could accept high inertia gravity and even a long time processing. The strongest column and double-layerd base could bear higher inertia gravity and improve dynamic responsiveness of the whole machine. The spindle vibration is smaller than most popular V4 vibration standard, providing better surface processing performance.. The fastest tapping speed can reach 6000 rpm and the smallest tooth can attack M1.2

cheap box way cnc vertical double column machining center

High rigidity moving parts with lightweight design for high speed and high precision parts processing, faster and more powerful parts processing machine. High strength gray casting iron machine body remains a high rigidity and stability even a long time processing. Special large span structure column and double-layerd base could bear higher inertia gravity and improve dynamic responsiveness of the whole machine.

Vertical Machine Center BF-1370V

The BF-1370V is designed with an ultra-rigid structure and X/Y/Z axis high precision linear guide and ball screw with locking preload design, which can provide you with fast, powerful, and stable machining performance. This machine can be widely used in the automotive, machinery, instrumentation, light industrial textile, and electronic instrumentation industries

Vertical Machine Center BF-1160V

BF-1160V is designed with an ultra-rigid structure and X/Y/Z axis high precision linear guide and ball screw with locking preload design, which can provide you with fast, powerful, and stable machining performance. It can be widely used in the automotive, machinery, instrumentation, light industrial textile and electronic instrumentation industries.

Vertical Machine Center BF-650V

The BBT40 spindle is supported by high-precision ceramic bearings to minimize noise, reduce vibration and suppress heat growth, which will help improve machining accuracy and surface finish. With a maximum 1G acceleration (3 Gs in Z axis), the machine is capable of handling most processing tasks at fast feed rates of up to 30 m/min. It is equipped with a powerful chip flushing device that removes chips from the cutting area without breaking.

Vertical Machine Center BF-850VP

The BF-850VP is a high precision vertical machining center. It adopts an ultra-rigid structure, X/Y/Z axis high precision linear guide and ball screw with locking preload design, which can provide you with fast, powerful, and stable machining performance. This vertical machining center can be widely used in the automotive, machinery, instrumentation, light industrial textile, and electronic instrumentation industries.

Vertical Machine Center BF-1166VP

With an ultra-rigid structure, high precision linear guide and ball screw, this mini CNC is suitable for high precision parts machining and mold machining. It can be widely used in the automotive, machinery, instrumentation, light industrial textile and electronic instrumentation industries, and can fully demonstrate high precision and high-efficiency machining capability at a very reasonable cost.

BAOFENG BF-8032L Double Column Machining Center

Baofeng CNC Double Column Vertical Machining Centers combine proven machine design with advance technology in control and manufacturing. Reliability and performance make this series a favorite among demanding CNC work shops and in-house productions alike.

BAOFENG BF-6032L Double Column Machining Center

The new CNC Woodworking Machine BF-6032L changes the game in ways that you never thought possible. Portal frame structure, traveling worktable (X-axis), spindle box traveling (Z-axis), saddle traveling on the beam (Y-axis), square ram design and twice speed-reducing with retarders offer low-speed constant torque and high-speed constant power cutting.